In this article, I would discuss what fiber optics are and how they work in industrial photoelectric sensing. Continue reading to learn key terms and the fundamentals of fiber optic systems and assemblies.

Historical Background of Fiber Optic Sensors

John Tyndahl discovered the principle name Total Internal reflection in the year 1854. Fiber optics is a type of optics that uses bundles of thin plastic or glass fibers to function on this principle.

When Tyndahl shined a beam of light through a torrent of water, the light tended to bend with the water as it arced towards the floor, rather than emerging straight from the stream as one might anticipate. Tyndahl noticed that light was transmitted via the water stream. The light beams inside the water rebounded against the water’s internal walls, containing them.

What is a fiber optic sensor?

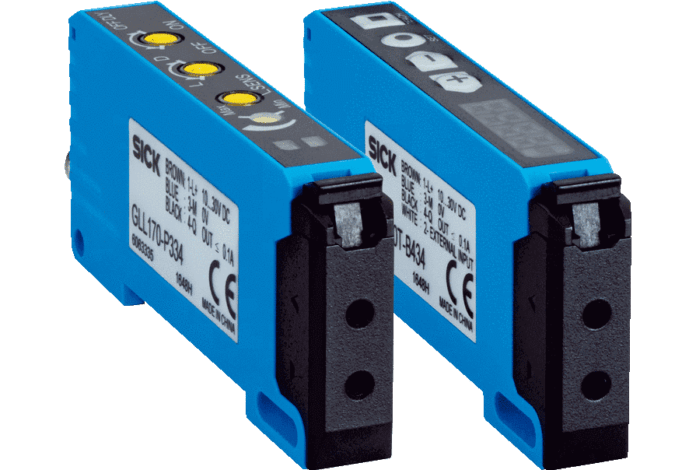

A Fiber Optic Sensor uses an optical fiber cable to transmit light from a Fiber Amplifier Unit to a Fiber Unit to detect things in restricted spaces.

Main Components of Fiber Optic Sensors

The core components of a modern fiber optic sensor are as follows:

Amplifier:

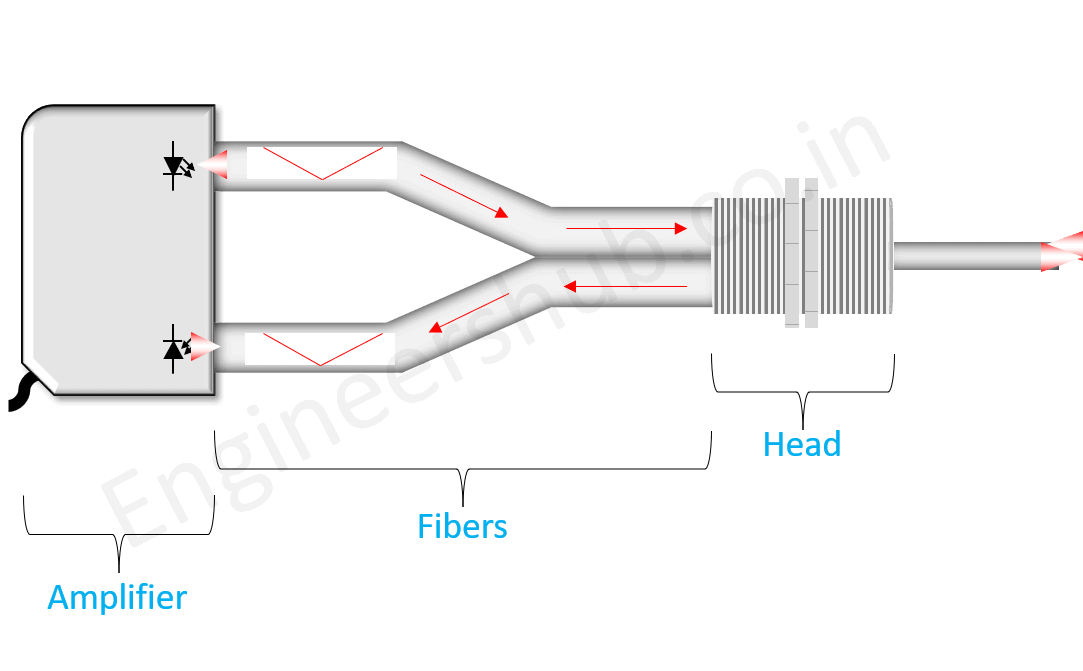

The amplifier Houses the light source, a detector for processing returned light, an operator interface for configuring sensor operation, and an output signal for use by other process equipment.

Fiber:

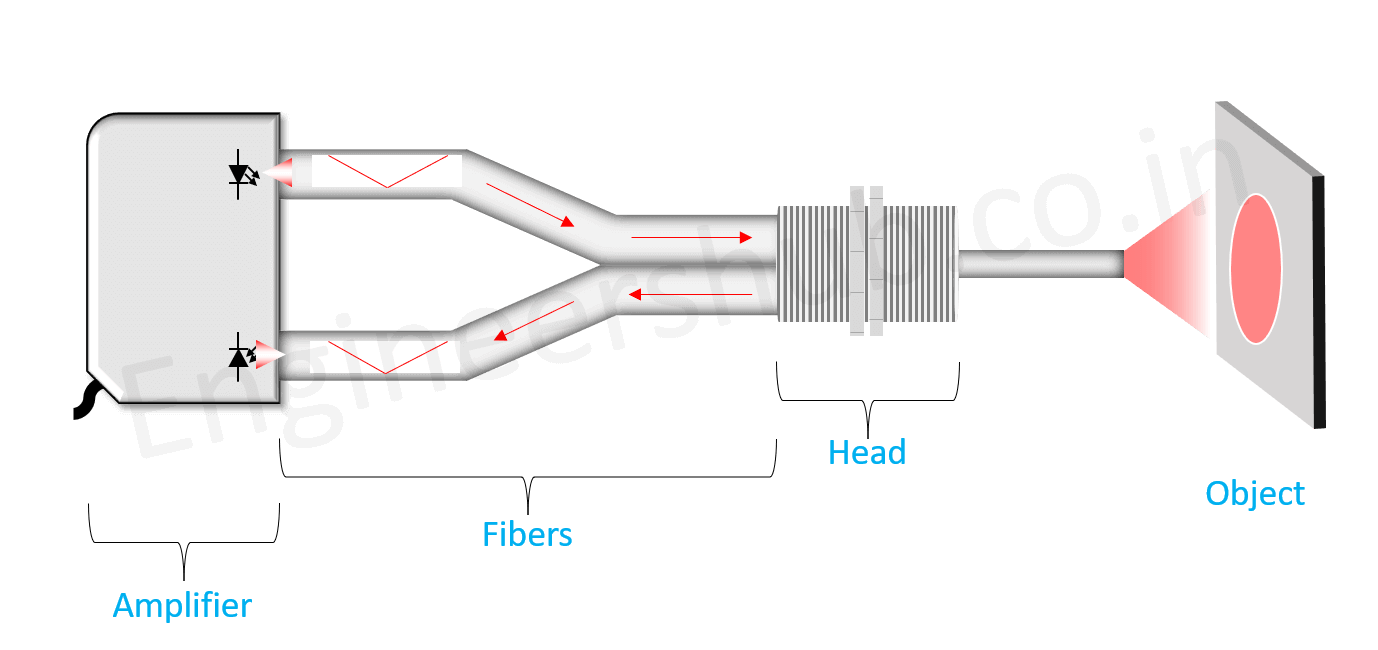

The Fiber is responsible for guiding light from the amplifier to the item being sensed, as well as returning incident light to the amplifier for detection and processing.

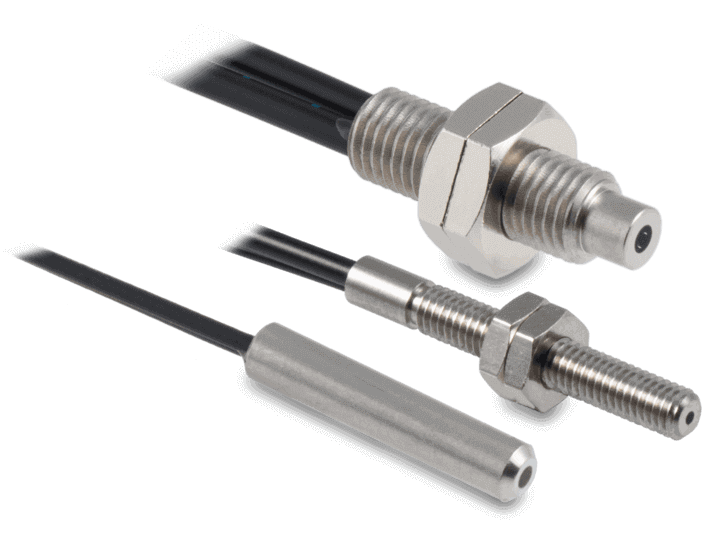

Fiber Head:

This component helps to guide and mechanically attach the fiber into place. The head, which can be fitted with a tiny lens to shape the light as it escapes the fiber or modifies the acceptance angle for incoming light, can also shape the light as it exits the fiber.

The sensor illuminates the item with one fiber and returns the reflected or incident light to the detector with another fiber. Both fibers unite in the fiber head to form a compact device capable of illuminating and sensing the presence of a small object in the example below.

How does a fiber optic sensor work?

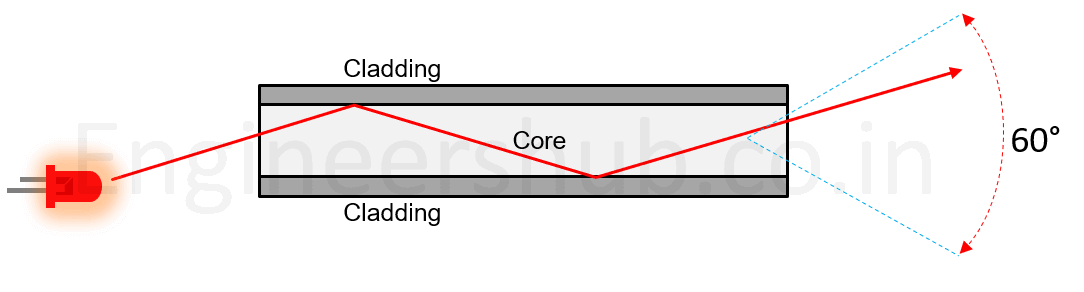

The fiber optic sensor works on the principle of total internal reflection.

A center core with a high refractive index is surrounded by cladding with a low refractive index in optical fiber. When light enters the core, it is guided along with the optical fiber by repeating total internal reflection at the boundary of the less refractive cladding. By the time light exits the optical cable and strikes a sensing object, the angle of light passing through it has increased to around 60 degrees.

Modern fiber optic sensors provide the option of selecting the control output.

DARK ON: When the light intensity sensed by the light detector falls below the reference, the output switches ON.

LIGHT ON: When the light intensity sensed by the light detector exceeds the reference, the output turns ON.

Construction of Fiber Optic Sensors

Now let us understand the construction of fiber optic sensors. Knowing this, it would be easy for you to select the fiber optic sensors for your application.

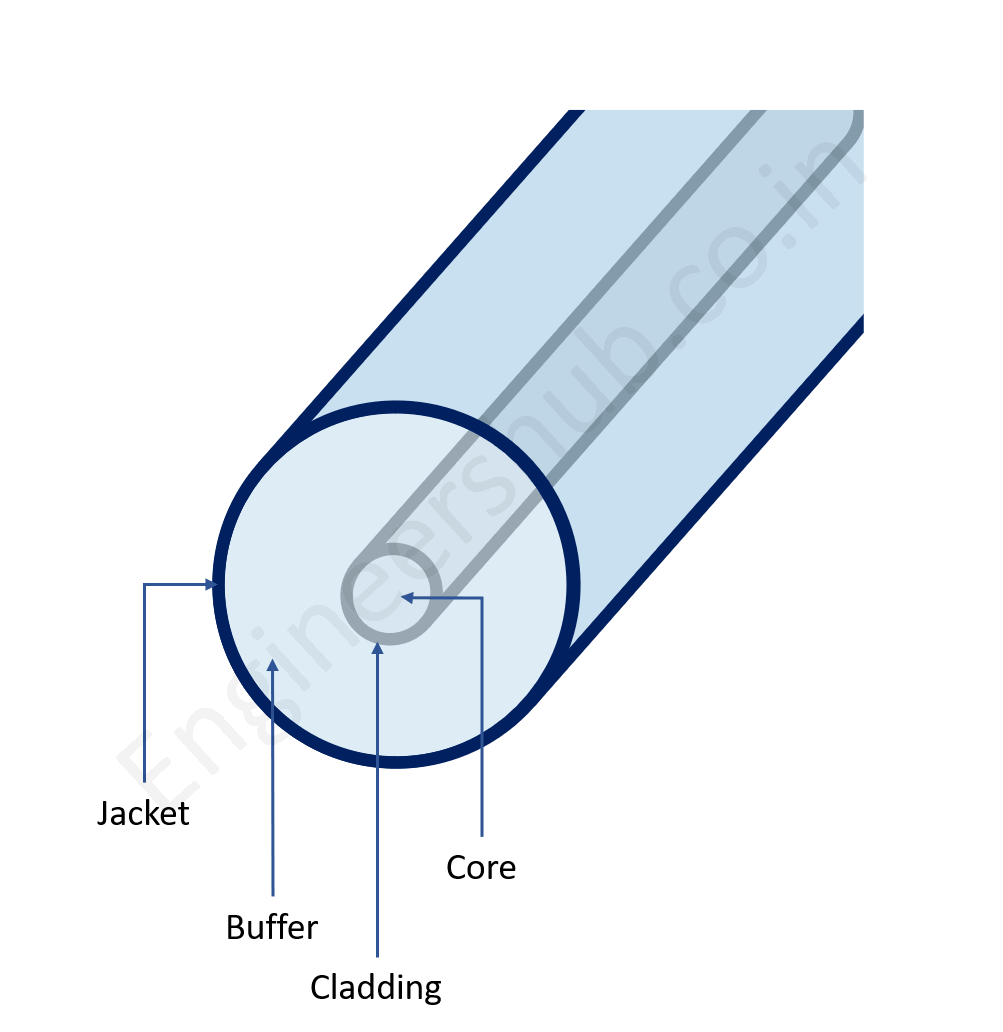

Fiber Optic Cable Construction

Starting with the core, the core is made of a single filament transparent glass or polymer is used to start the fiber manufacturing process. For optimal light transfer into and out of the fiber, the ends of this material must have a smooth cut.

If the core fiber is bonded with a material with a lower index of refraction, the efficiency of light transmission in a fiber can be enhanced.

The cladding surrounds the core fiber and improves transmission efficiency by improving the total internal reflection effect.

A Buffer and Jacket can then be applied to the fiber for abrasion resistance, chemical resistance, and mechanical stability.

Fiber Optic Sensor Head Construction

The illumination and acceptance angle of standard PMMA fiber heads is roughly 60 degrees.

PMMA (polymethyl methacrylate) is a type of plastic material. Acrylic, acrylic glass, perspex, or plexiglass are the trade names of PMMA.

As a lightweight or shatter-resistant alternative to glass, this plastic is frequently employed in sheet form.

It’s also used as a casting resin, in inks and coatings, and a variety of other applications.

An auxiliary lens can be attached to the fiber head to improve the identification of small pieces or small object features. The lens will focus on the light source and restrict the acceptance angle, making precise detection possible.

Auxiliary lenses can also be utilized to extend through-beam fibers’ maximum sensing distance.

Fiber Optic Sensor Amplifier Construction

The amplifier is made of PC material.

Polycarbonate is mostly employed in electronic applications that benefit from its overall safety properties. It is utilized in a variety of electrical and telecommunications hardware devices because it is a good electrical insulator and has heat-resistant and flame-retardant qualities.

Features of Fiber Optic Sensors

Fiber optics provide several advantages in photoelectric sensing, including their small size, versatility, and ability to tolerate harsh situations where conventional sensors could be unavailable.

- Small Size for confined sensing areas.

Fiber optic assemblies can be positioned and mounted in compact locations due to their tiny size and flexibility. Single strands of optical fiber are used in most plastic fiber optic setups. They can be routed via very tight spaces. Plastic fibers can also withstand repetitive flexing. For sensing applications on reciprocating machines, pre-coiled plastic fiber optics are offered.

- Consistently good in performance in difficult or explosive conditions.

Fibers can be made to withstand corrosive materials or excessive dampness, and they are also resistant to electrical noise. Because fiber optics do not contain any electrical circuitry or moving elements, they may safely “pipe” light into and out of hazardous sensing sites.

Furthermore, most glass fiber optic systems are quite durable and operate well in harsh environments.

In severe conditions, sheathing materials like polypropylene, Teflon®, and nylon are utilized to protect both plastic and glass fiber optic assemblies.

Fiber optic assemblies can also resist high degrees of vibration and mechanical shock since optical fibers have a low bulk.

- Flexibility to meet many different applications requirements.

Flexible probes in some fiber optics can be “formed” to meet the physical and optical requirements of a specific application.

Where Fiber Optic Sensor can be used?

- Papercutting machines

- Vibrating feeders

- Counting pills

- Detecting small objects

- Semiconductor processing equipment.

- Moving machines and robotic arms.

Reference: Sensors Handbook, Second Edition by Sabrie Solomen.