Switching OFF or ON of the loads like motors is often controlled by contactors.

What to do if suddenly load doesn’t get started? You may need to check the contactor.

Here, I will tell you – how to troubleshoot contactors?

I would share my experience.

I faced the problem of ‘Contactor chattering’.

If you do not know anything about contactor and its working principle, check out this article ‘How a Contactor works‘. I would suggest you know about the working principle of contactors before you start troubleshooting. That will make troubleshooting easy.

It was a new Air Condition unit where we faced this problem. I am telling you what the problem was exactly. As soon as we start the air condition unit, the contactor that is for controlling the compressor, starts chattering.

Let me tell you, what is chattering. The contactor switches ON/OFF rapidly and makes an unusual sound. This unusual sound is called chattering.

Often when something goes wrong with the system, we simply doubt the device first. We did the same. Somewhere at the back of my mind, I knew that the problem was not with a contactor, but still, my subordinate and I decided to check the contactor.

I would share tips to troubleshoot the contactor, the way we did.

Remember that, the tips, which I am going to share, are not only for the above-mentioned problem. You can follow it when you want to be sure, whether the problem is with the contactor or not in any breakdown. You can also consider it as guidelines for troubleshooting contactors.

How to Troubleshoot Contactors?

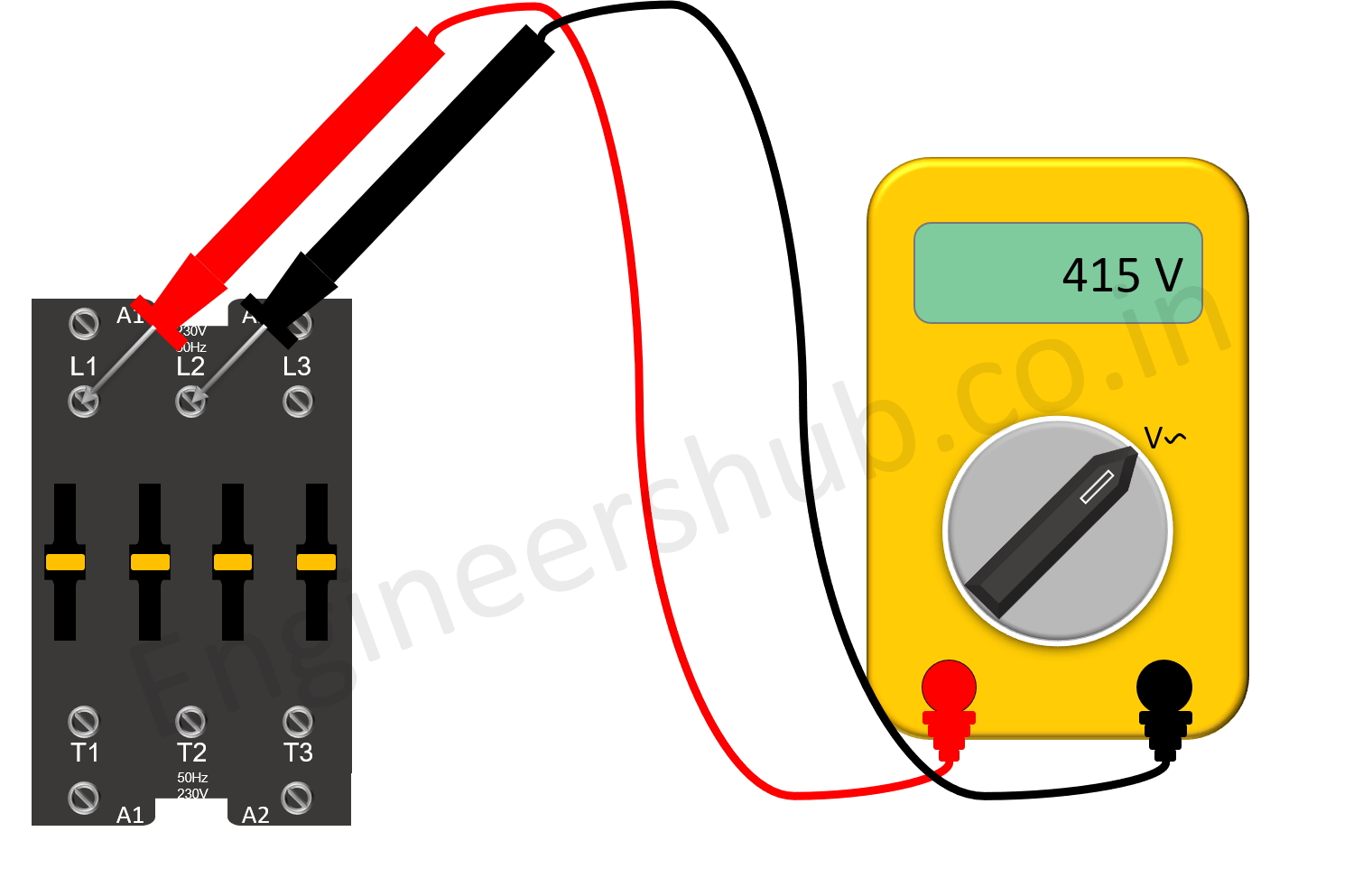

Check the voltage potential across the coil of the contactor.

Remove all the wires from L1, L2, L3 and T1, T2, T3 for safety point of view. Put the multimeter in AC voltage mode (as shown in the image below). Put one lead of multimeter at A1 and other at A2. Switch ON the control circuit. If the voltage is near to the rated voltage of the coil, it means that there is no problem with the voltage coming to the coil.

Check the coil of the contactor.

Remove the wires from the coil. Put the multimeter knob in ohms mode. Place one lead at A1 and the other at A2 just as you did to check the voltage across the coil. If the multimeter shows infinity, it means that the coil is open. In case, it shows zero ohms, it means that the coil is short.

If the multimeter is showing some resistance it means that the coil is ok.

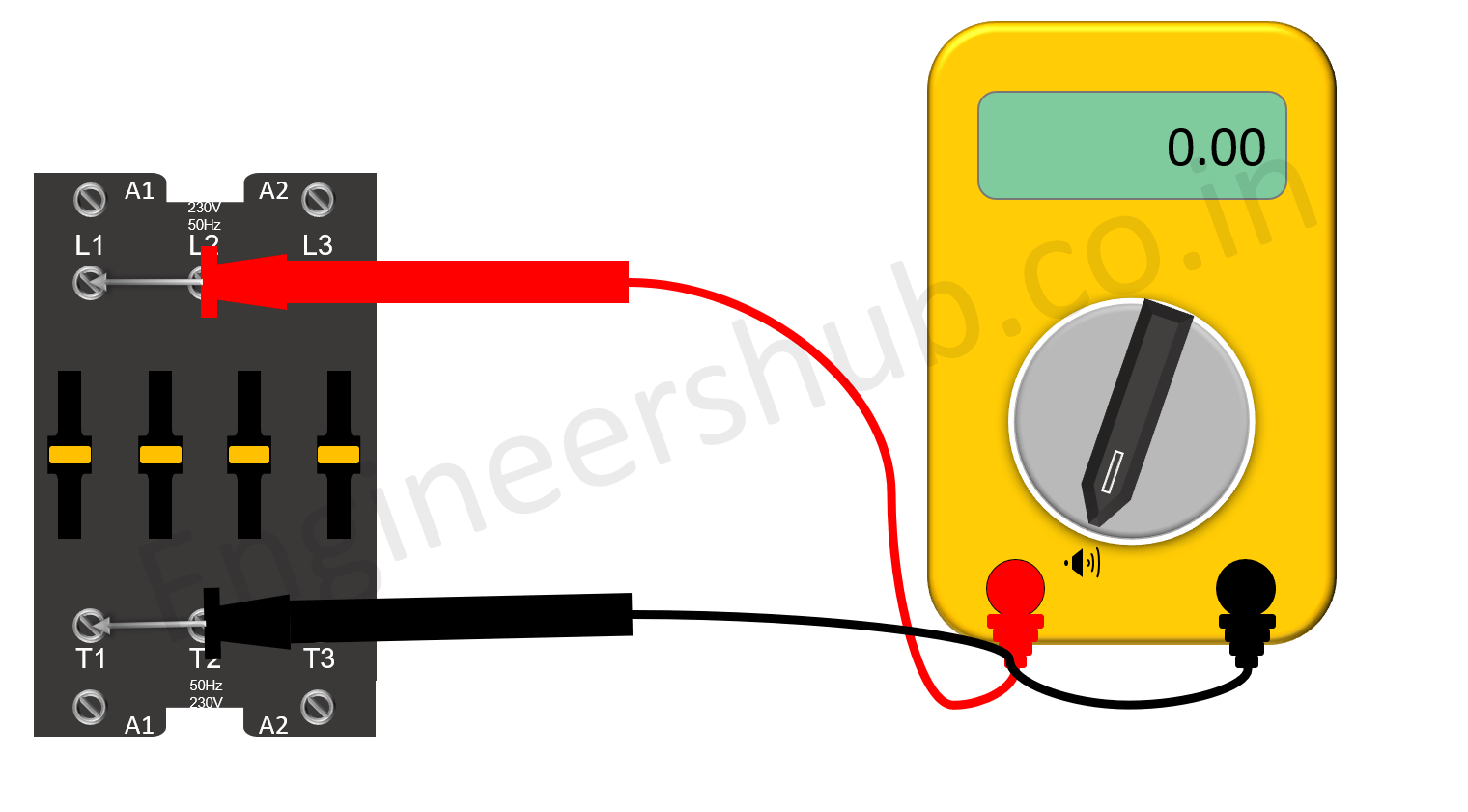

Check the Contacts of the Contactor.

Set the multimeter knob in continuity mode. Put the red lead of the multimeter in L1 and the other black lead to T1. You must hear the sound.

On display, it should show zero or near to zero ohms, in this way also, you can verify (as shown in above picture).

Repeat the same procedure for L2 and T2, L3 and T3. You must get continuity indication. If you are not getting continuity for all three, either you need to replace a few parts or the entire device.

Check the voltage between the terminals.

Connect main wires. Switch ON the power circuit. Put the multimeter knob into the AC voltage mode. Check the voltage potential between L1 and L2, L2 and L3, L3 and L1. Note down the voltage readings. Now switch ON the control circuit associated with the contactor you are troubleshooting. Check the voltage potential between T1 and T2, T2 and T3, T3 and T1. Note down all the readings again.

The voltage potential between L1 L2 and T1 T2, L2 L3 and T2 T3, L3 L1 and T3 T1 should be the same.

Otherwise, either check for the loose connections, if any. Else, you need to replace the contactor.

So this is how you can be sure that whether the problem is with contactor or not.

In our case (the problem which I shared earlier in this article), the problem was not with the contactor. It was with a Low-Pressure switch, which was malfunctioning.

Thus, I would recommend first to check the control circuit and power circuit associated with the device thoroughly and then you check the device. This will reduce the time.

Here, I am giving you the solutions of common problems arise in contactor. It may help you while troubleshooting.

What causes a Contactor to not pull in?

This happens due to few reasons. a. It could be because the coil is not getting the rated voltage. Solution: Check the control circuit from where the coil is energized. Sometimes the interlock like an emergency push button, a limit switch, etc. connected in series may malfunction. b. Another probable reason could be the failure of the coil. Solution: Here, you cannot rewind the coil if the problem is due to coil failure. Replace the contactor with the new one of the same rating.

When should a contactor be replaced?

Consider replacing the contactor in the following condition: a. When the contactor is not pulling in due to a damaged coil. b. Silver cadmium tips are worn. c. Discoloration of moveable contact.

What causes the coil of the contactor to burn out?

In general, the coil part of the contactor may burn out due to the following reasons, - Overvoltage - Voltage fluctuations - Over-temperature - Under voltage

Very helpful

Like!! Thank you for publishing this awesome article.

Thank you very much….

I have been browsing online more than 4 hours today, yet I never found any interesting article like yours.

It’s pretty worth enough for me. In my view, if all

website owners and bloggers made good content as you did, the

internet will be much more useful than ever before.

this article is very helpful to tackle problem..

thank you.