Can you find contactors in your house?

Of course, you can find contactor in the starter circuit of your bore well pump.

Here, I will explain ‘how a contactor works’ along with its history.

History and Background of Contactor

In 1890s hand starters were used to start the DC machines. It was very difficult for engineers to isolate the machine from the main supply.

A German engineer Hein Moeller developed the world’s first oil contactor. But this contactor was robust and expensive. Due to that reason, OEM’s of heating, ventilation, and air conditioning system requested to develop definite purpose contactors. Definite purpose contactor means contactor made for a specific application.

In 1950’s definite purpose contactors developed and since then, we observe various changes in the design of the contactors. Today we have many options to choose the contactor for specific load according to the rated voltage and current of the load.

What is the purpose of Power contactors?

Before we move on to the working principle of the contactor, let me make you understand, why we should use contactors. Generally, in industries, the heavy loads like induction motors, lightings, capacitors, HVAC system, etc. often require to switch ON/OFF. Suppose, if any abnormal condition arises, the load needs to be switched off.

The abnormal condition could be either a short circuit or an overload. Sometimes manually also the load needs to be switched off. In such situations, the load needs to be isolated from the power supply. Contactor isolates the load from the power supply and that is the purpose of the contactor. You can also consider contactor as a switching device.

Remember that contactor is not a protective device.

How a Contactor works?

Now coming to another interesting point and that is ‘how it works’. Power contactors can make, carry and break the current.

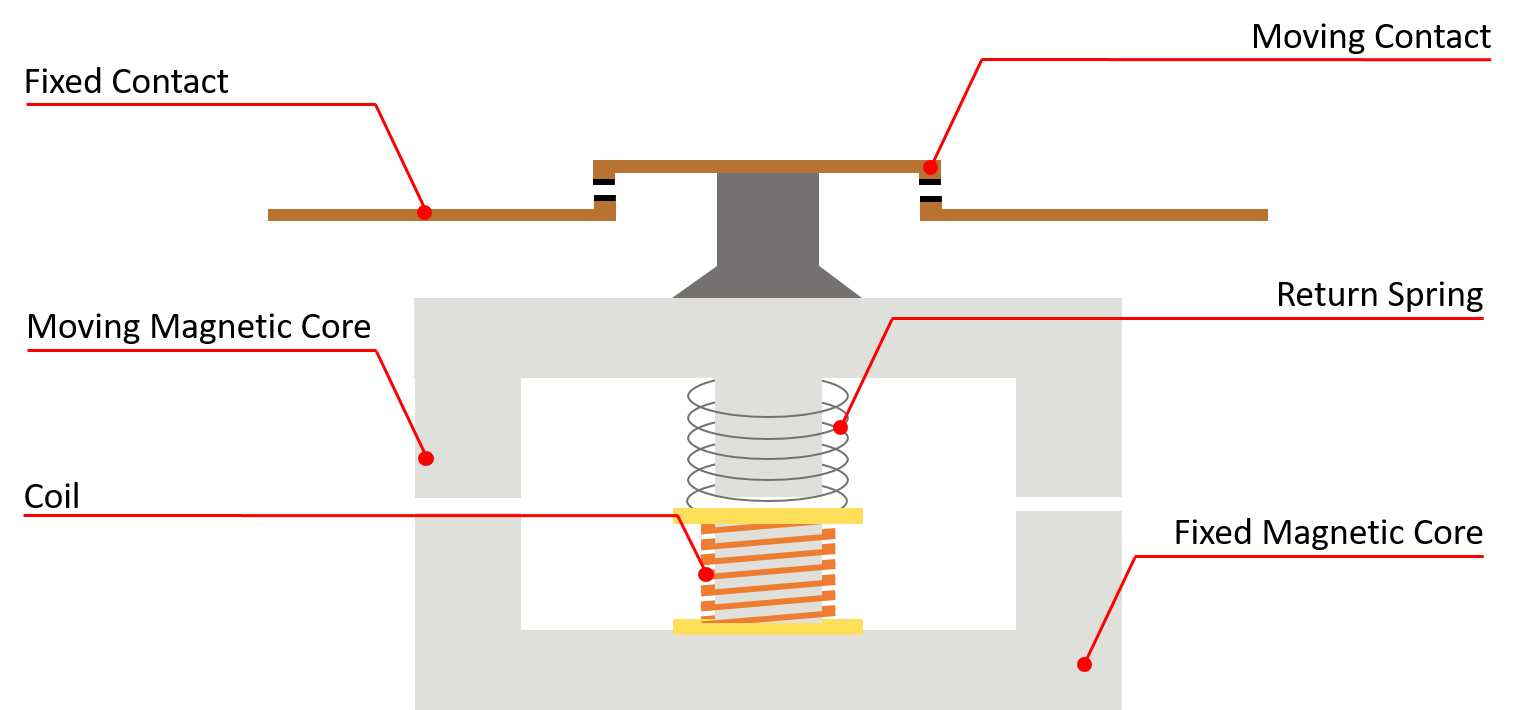

It consists of a coil and two separate laminated cores one fixed and another moving making an electromagnetic system as shown in below image.

On supplying definite voltage to the coil, the moving core gets attracted towards the fixed core, closing the contactor. This completes the electric circuit through the contact system. When the control voltage is removed from coil, the contactor opens up.

Coming to the contact system of the contactor. The power contactor has a two-contact system, which can carry separate electrical circuits.

- Main Contacts: Carries the main power supply to the load. The main contacts are always Normally Open (NO), which gets closed when the coil gets energized – allowing the main supply to pass.

- Auxiliary Contacts: For hardware interlocking and sending a signal to PLC these auxiliary contacts are used. The Normally Open (NO) contact gets closed and the Normally Closed (NC) gets open when the coil gets energized.

Video Tutorial

You can also watch video tutorial on “How a contactor works?” on YouTube.

What are the parts of Contactor?

Now let us understand each part of the power contactor and their function.

Rubber padding

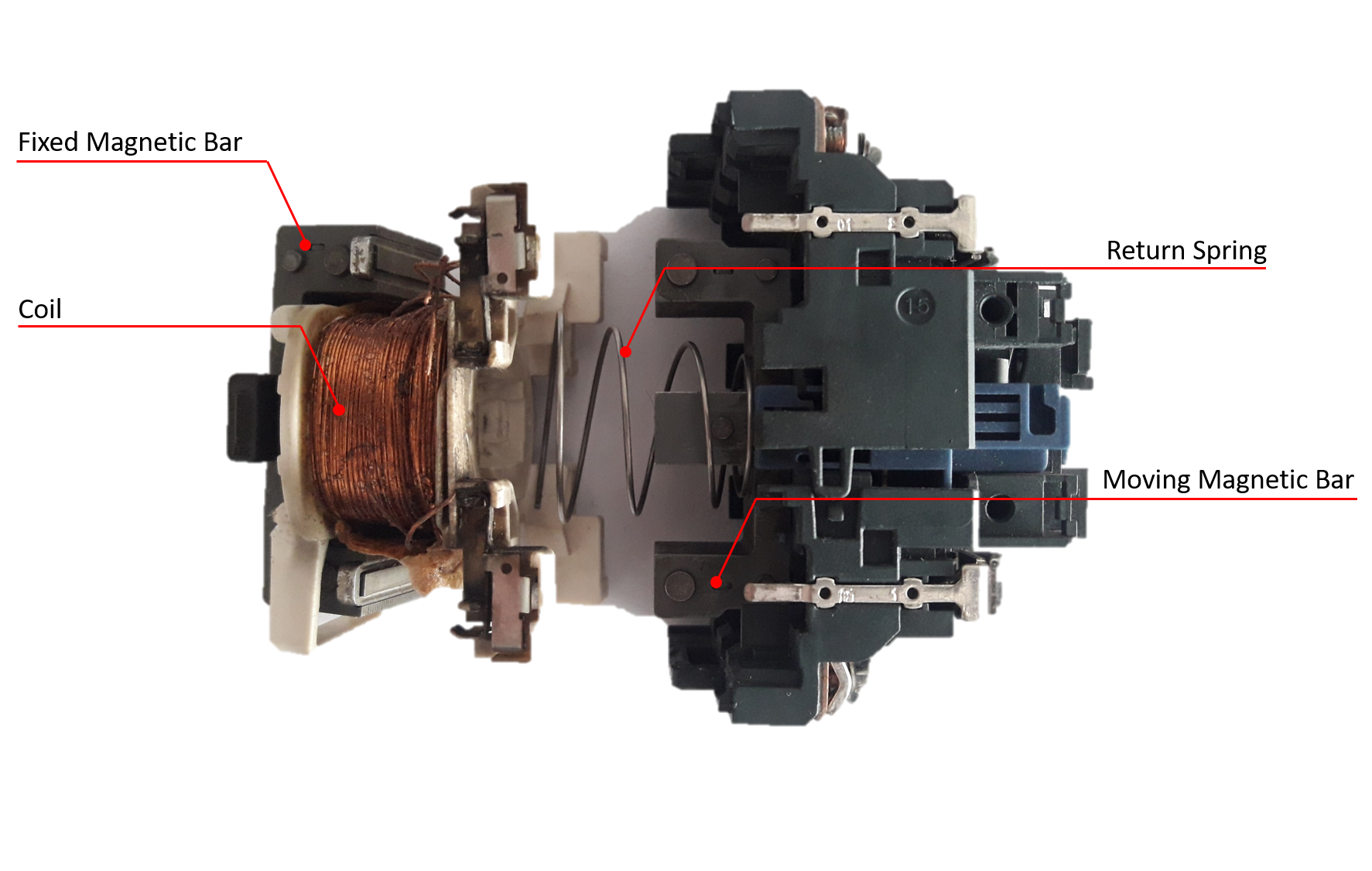

The contactor has a fixed magnetic bar and moving magnetic bar. Energizing the coil causes the moving magnetic bar to attract towards the fixed magnetic bar. This creates vibration inside the housing of contactor. Rubber pads absorb this vibration.

Magnets

In the picture, you can see magnetic bars. It has stacked lamination. Stacked lamination reduces the effect of eddy current losses.

Contact System

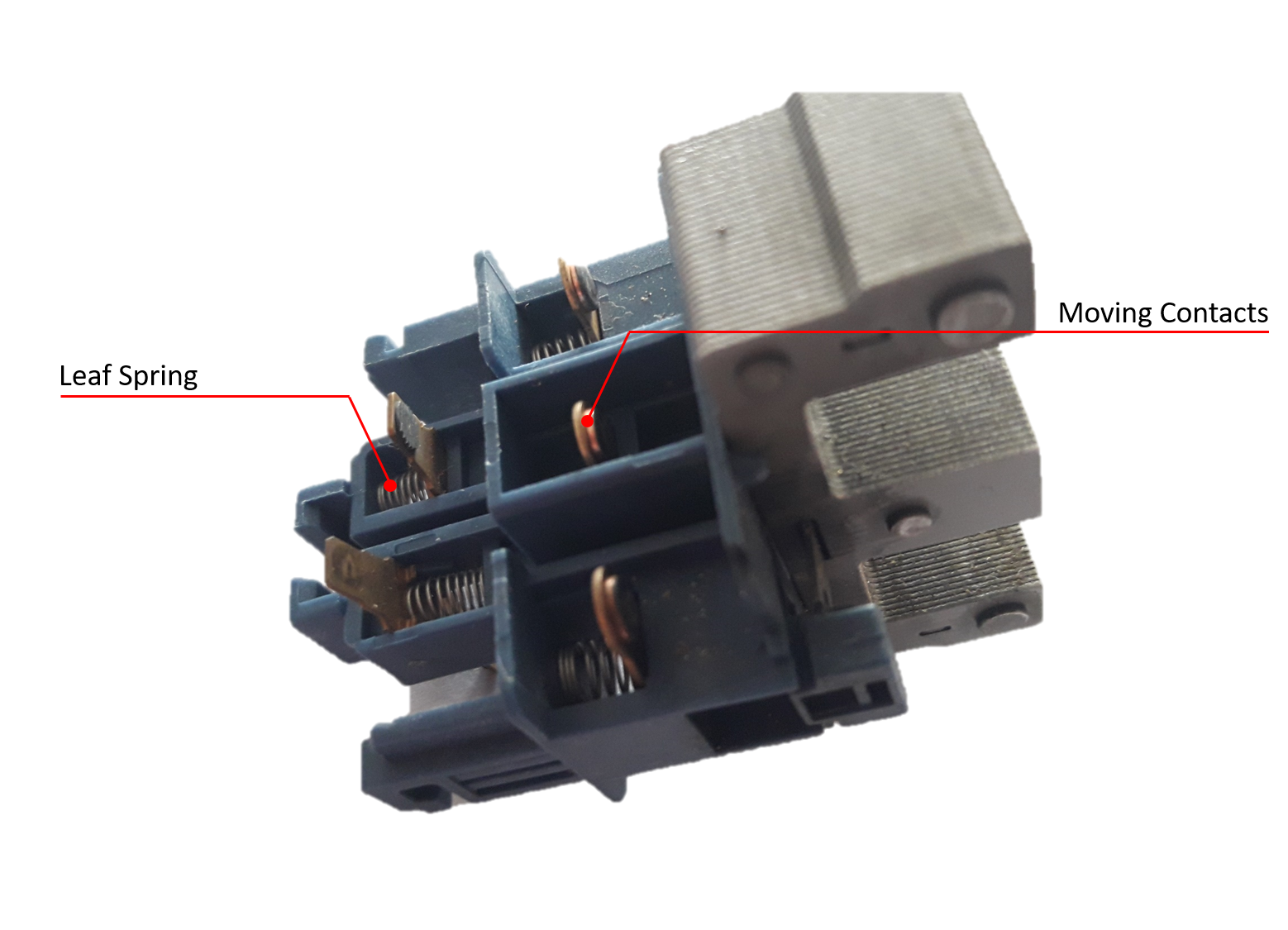

The current drawn by the load flows through this contact system. Generation of arc takes place between two contacts while the opening of the contactor. This results in damaging the contactor quickly. This reduces the life expectancy of the contactor. Therefore, the metal used for the contact system must have good anti-welding properties for having a longer life and it should be a good conductor of electricity as well. Generally, silver cadmium alloy meets the requirement for the contact system of the contactor. This alloy has good anti-welding properties and silver is a good conductor of electricity.

Leaf Springs

While the closing of the contactor, the moving contacts tries to bounce back which can break the electric circuit for fractions. The leaf spring ensures bounce free closing. Also, frequent opening and closing of the contactor makes moving contacts lose because of vibration. Leaf spring exerts certain pressure so that moving contacts can be held with fixed contacts.

Return Springs

It helps contacts to open during de-energizing.

Terminals

Serves the purpose of fastening the cables. They are made up of silver plated copper. Both power circuit and control circuits have terminals.

Auxiliary Contacts

Serves the purpose of feedback, alarm, interlock etc.

Arc Chute

Arc generation arises during breaking operation (breaking operation means opening) of the contactor. Quenching of arc takes place in arc chutes.

Housing

The housing of contactor is one of the important part. The reason is, it has to withstand the voltage potential. It must have good thermal withstand capacity and mechanical strength. Both SMC (sheet-molded compound) or DMC (dough-molded compound) meets the requirement.

Summarizing

Understanding the working and each part of the contactor can help you out in selecting the right contactor. Selection of the contactor depends on type of the application. This articles ‘Contactor: Types and their Applications‘ describes best regarding type of contactor suitable for various applications.

If you have any questions related to this topic, you can ask me in the comments section. I would answer you.

Take a look at frequently asked questions on the contactors related to this topic.

1. Why contactor is used?

Contactors can either make or break the electric circuit and that is what they are meant for. The loads need to be switched ON or OFF in normal or abnormal conditions. The contactor simply isolates the load from the power supply. Unlike control relays, contactors can make and break the circuit for many thousands of cycles.

2. What part of contactor is energized?

The coil of the contactor is energized. The coil of the contactor is available in different voltage ratings like 24 VAC, 24 VDC, 230 VAC, 110 VAC, etc.

3. What are contactor contacts made of?

While making and breaking of electric circuit arc produces between the contacts. This damages the contacts. Hence, the material should have functional properties like high resistance to arcing along with high electrical conductivity. Silver-cadmium alloys meet the requirement for the contact system of the contactor. However, copper, gold, platinum, and palladium can be used as contact alloys.

Very good information.