In this article, I am going to talk about different types of contactors and their applications. If you still do not know about the basics of contactors, no worries, you can find information in this article ‘Contactors: History and Working Principle’.

After knowing about the working principle of the contactor, you may wonder hearing that contactors are also available in different types.

A question arises, ‘why the different types’.

Well, there is a popular say, ‘Necessity brings Innovation’. In the case of contactor also, it completely fits in.

Let me give an example. Consider a 4-pole contactor controlling a group of single-phase load. It may happen that after certain cycles of operation the neutral contact damages resulting in neutral break condition. Schneider Electric brings out the solution by introducing Acti 9 iCT series contactor. This series of contactor ensures the long life of the contacts and hence, ensures the reliability of the operation of the load.

In addition, the different applications make companies to innovate new contactor technology. For example, the contactor selected for hoist application must meet the requirement as mentioned in IEC 60204-32.

That is why we have different types of contactors. Now let us understand each of them.

Types of Contactors

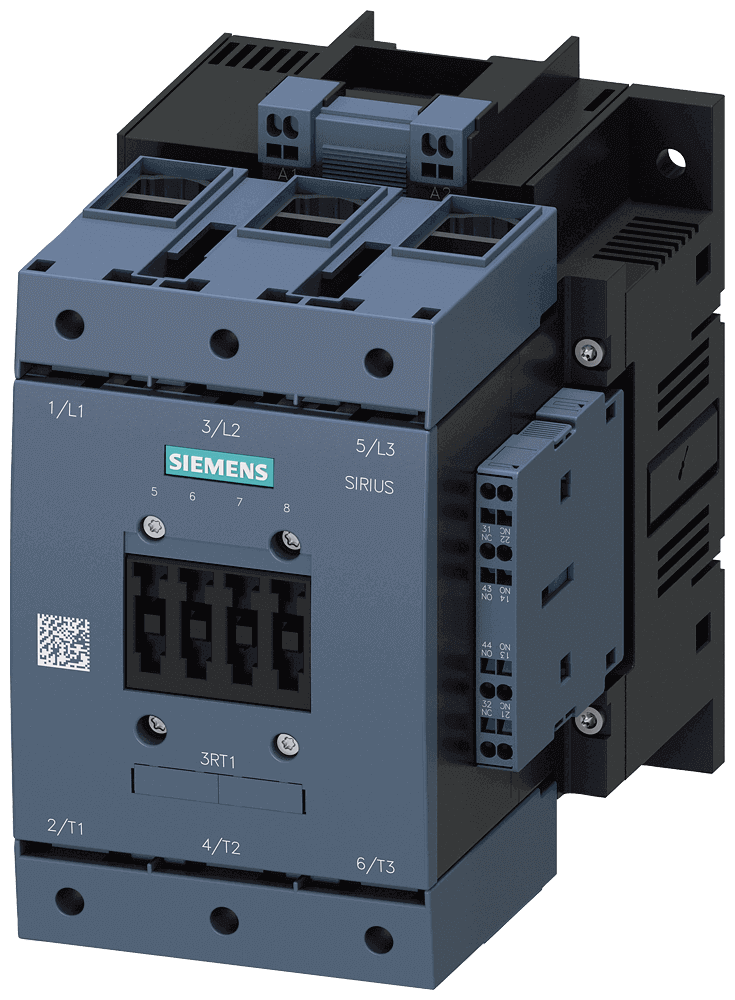

Power Contactors

It consists of the main contact system. Hence, these contactors are more suitable for running actual loads. These contactors can carry two different voltage potentials. One is for driving the load and another one is for actuating and giving necessary interlocks.

Applications: DOL, Star-delta, Forward-reverse starters’ use contactors to start/stop induction motors. Heating loads also use contactors for their start/stop operation.

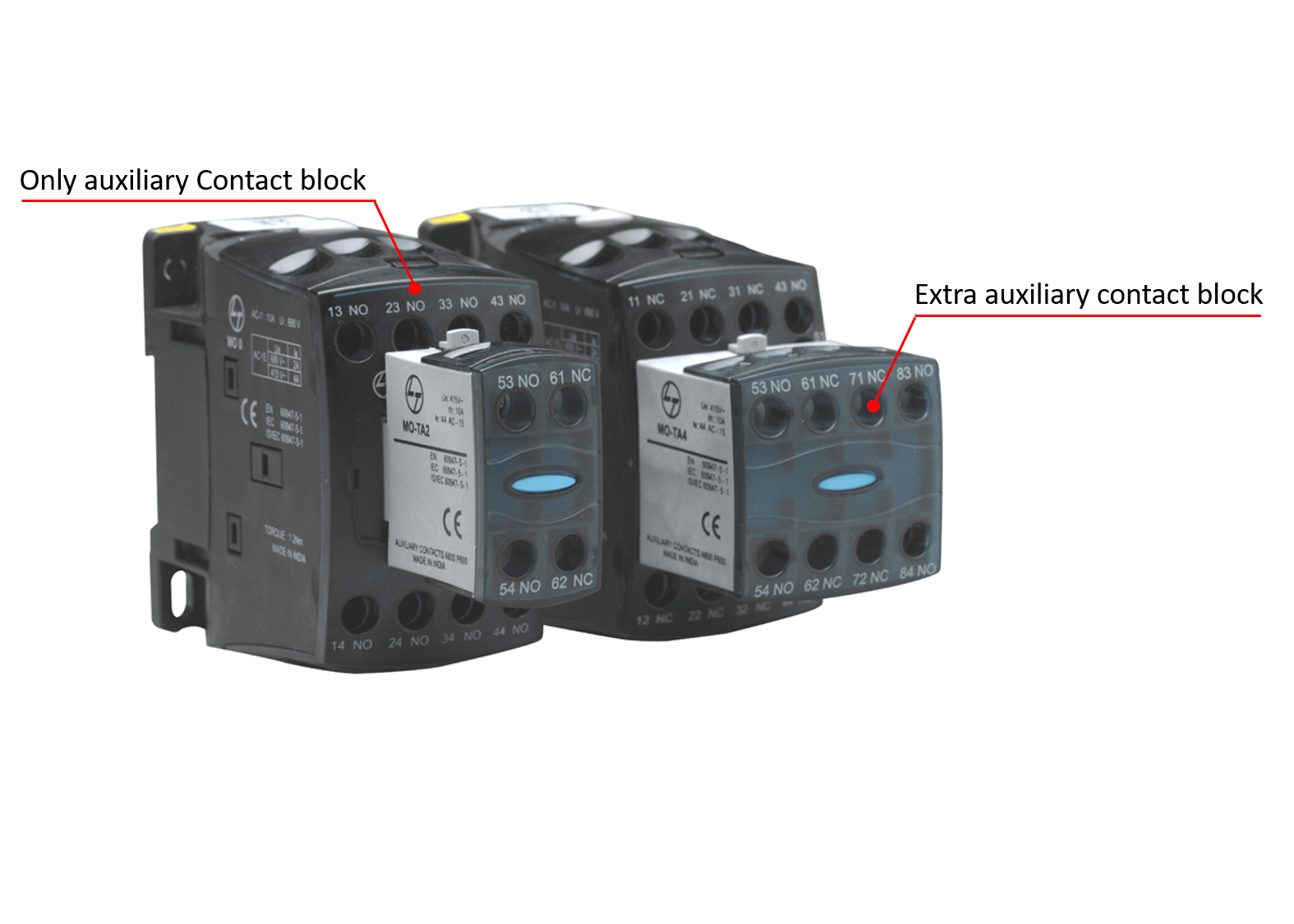

Control Contactors

It consists of a coil and more number of auxiliary contacts. It does not consists of the main contact like power contactors have.

Applications: MV breakers control circuits.

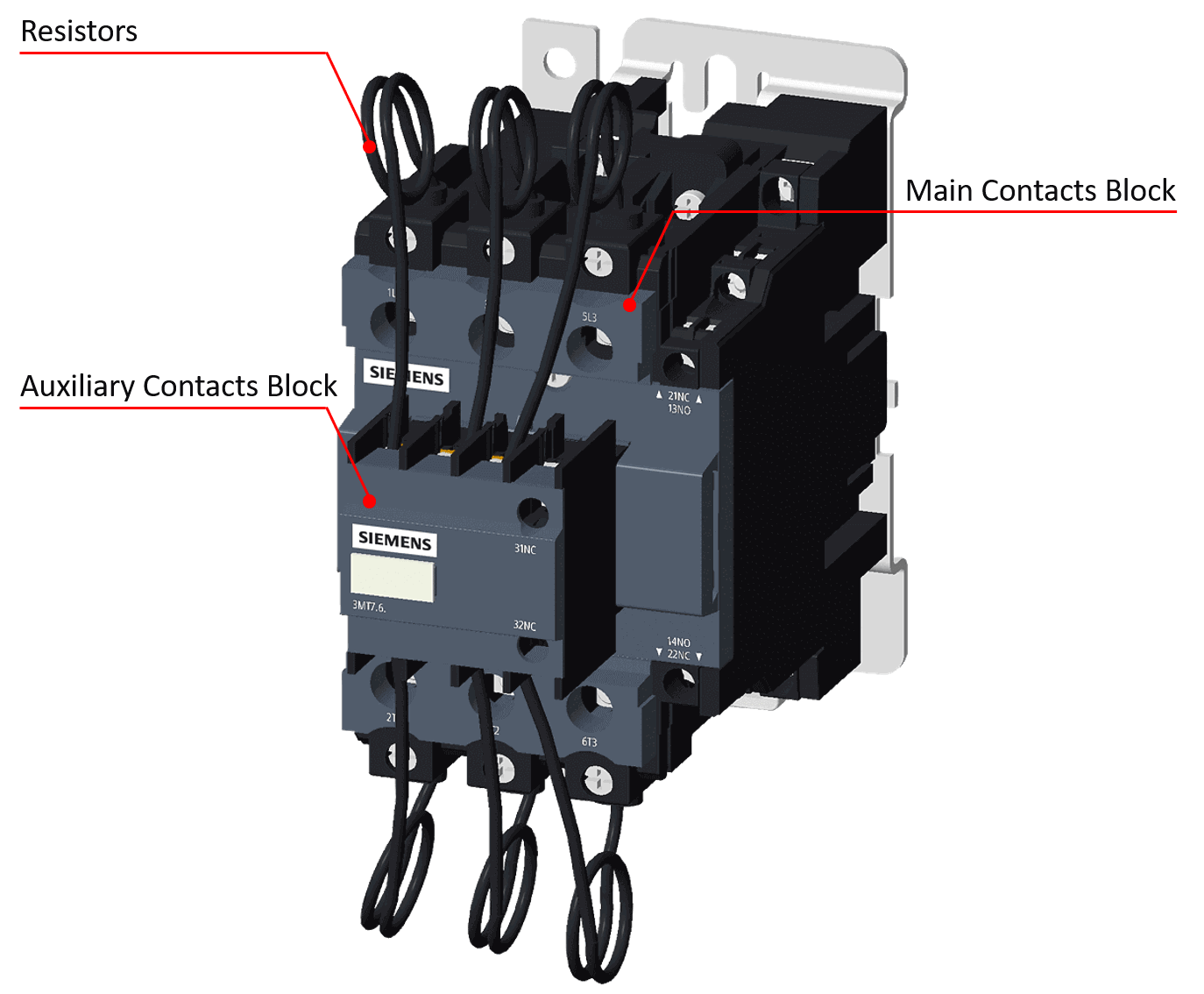

Capacitor duty Contactors

During starting, capacitors acts as short-circuit, so very high current flows through the capacitors. This high current contactor has to sustain. Hence, capacitor duty-cycle contactor is the best choice. It consists of auxiliary contact block having resistors as shown in below figure. During the energized condition, first, the auxiliary contacts close so that the resistor comes in series limiting the inrush current. After a few milliseconds, the main contacts close. The auxiliary contacts automatically open up once the main contacts close.

Applications: Power Factor Capacitor switching ON/OFF.

AC Contactors

AC contactor coil works on AC supply. Hence, named as AC contactor.

DC Contactors

DC contactor coil works on DC supply. Hence, named as DC contactor.

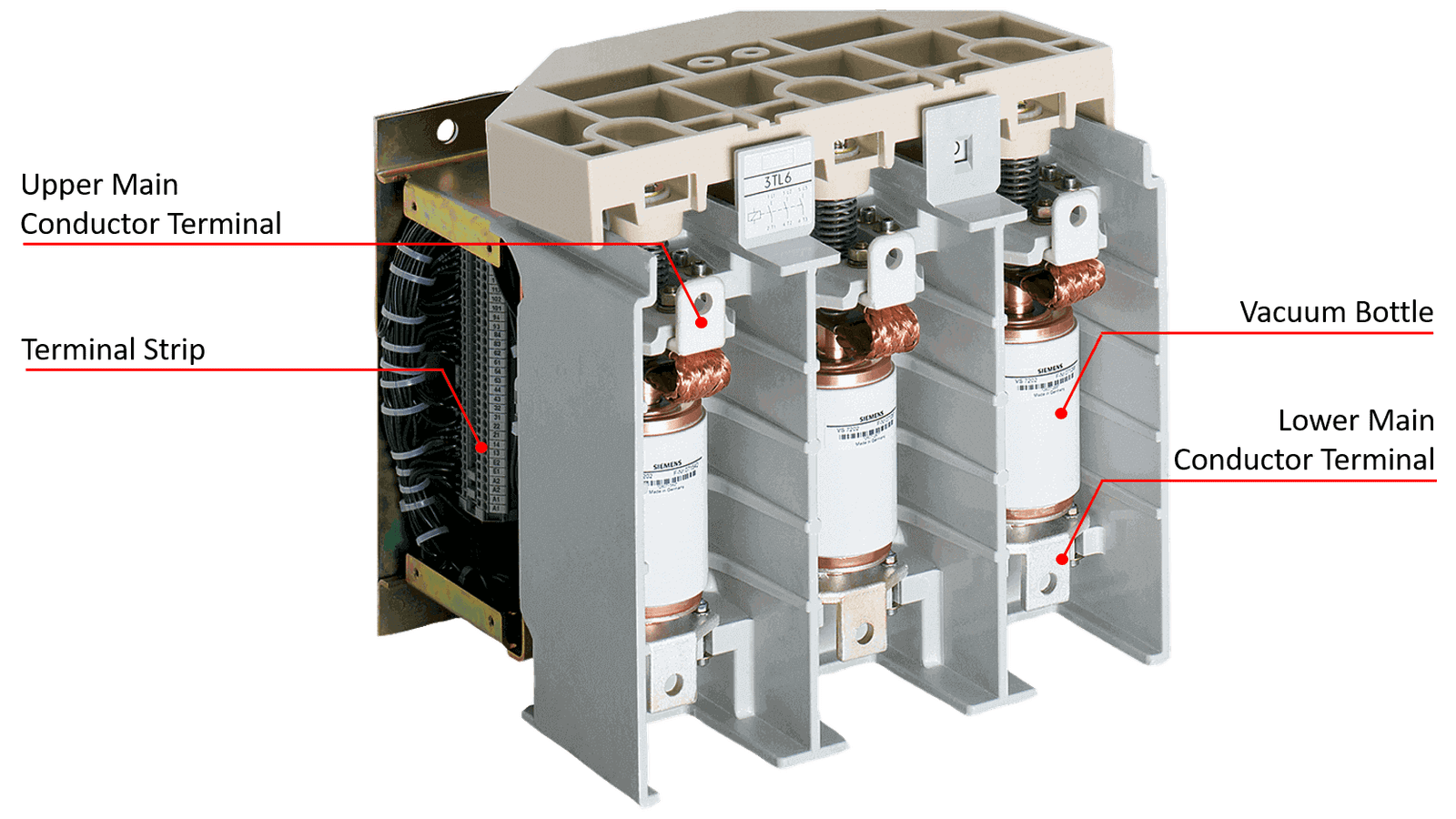

Vacuum Contactors

It has two separate parts. One is a medium voltage part and another one is a low voltage part. The main contacts are inside the vacuum bottles as shown in the below figure. The upper and lower conductor terminals and main contact system together form medium voltage part. The operating mechanism and control unit forms low voltage part of the vacuum contactor. The magnetic system is used to operate the interrupter inside the vacuum. These contactors have high electrical life.

Applications: Due to high electrical life, these contactors are used in starting conveyors, compressors, elevators MV three-phase motors. They are also suitable for switching operations of reactors, furnaces, etc.

4-pole Contactors

This type of contactors has three poles for 3-phase connections and one pole for neutral connection.

Applications: This type of contactors is more suitable for controlling a group of lighting loads.

Summarizing

Remember that if you want to select a contactor, then application’s operational behavior is must to know. Knowing application and then selecting the contactor would help you to increase the electrical and mechanical life of the contactor. Hence, you can decrease the maintenance and increase the system availability inside the factory.

Iam very much interested in the document, please sir let me get more engineering education from you sir, iam from Kenya.thank you.

Very educative article.