Statistics say that on average India alone imports around 1 million barrels of crude oil per day from Russia in the financial year 2022-23.

Imagine the financial impact on buyers or sellers if the measuring device gives an erroneous reading. Accuracy does matter in this case.

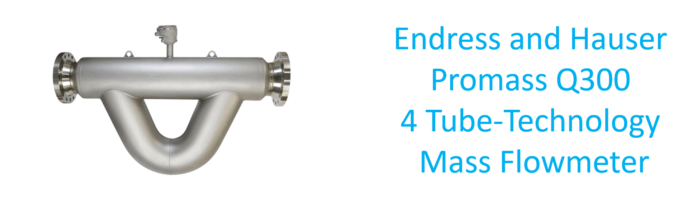

To have more accurate reading Endress+Hauser has come up with revolutionary 4-tube technology Mass Flowmeter.

If you know the working of the Mass flowmeter, generally it has twin tubes to measure the flow of liquid.

Endress+Hauser claims that their 4-Tube technology gives even more accurate reading and it has other benefits too. In this article, we would be discussing 4-tube technology working, its benefits, and its applications.

Key Features of 4 Tube-Technology Mass Flowmeter

- Excellent repeatability (0.025%) and the highest measurement accuracy (0.05% o.r.) over the whole measuring range: numerous external, authorized oil and gas calibration centers for testing and confirmation.

- The proprietary MFT (Multi-Frequency Technology) provides excellent measurement performance for liquids containing microbubbles.

- Excellent density measurement accuracy: 0.2 kg/m3 (0.0002 g/cm3) (measured by H&D Fitzgerald/UK).

- The industry’s best turndown and zero-point stability.

- Can be employed in low temperature ranges down to -196 °C (-321 °F) or for process temperatures up to 205 °C (401 °F).

How do Endress and Hauser ProMass Q300/500 4 Tube Technology Mass Flowmeter work?

The ProMass Q300/500 Mass Flowmeter works comes with 4 tubes. There are two independent measuring systems.

The Mass Flowmeter takes measurements based on Coriolis Principle. However, the Coriolis forces are pre-generated in a controlled manner inside the Mass Flowmeter. When translational and rotational motions are combined, these forces are always present in the system.

The formula for flow measurement is –

Fc = 2 · ∆m (ν · ω)

Where,

Fc = Coriolis force

∆m = moving mass

ω = rotational velocity

ν = radial velocity in a rotating or oscillating system

In twin-tube technology only a single measuring system is available. The two measuring tubes through which the fluid flows are excited simultaneously at different resonance frequencies.

The moving mass m, its velocity v inside the system, and therefore the mass flow are all factors that affect the Coriolis force’s amplitude.

There are two sensors, Sensor A and Sensor B. Both sensors detect oscillation rather than a steady rotating velocity. In that way, flowing fluid is measured in two parallel measuring tubes that oscillate in opposition to one another.

Photo Credits: Endress+Hauser

In the above picture, the first instance depicts that the fluid is at a standstill means not flowing through the tubes. In that condition, the oscillating frequency sensed by Sensor A and Sensor B would be in phase with each other.

The second instance depicts the condition of fluid flowing through the tubes. Sensor A and Sensor B would register the phase difference of the oscillation at the inlet side of the tubes.

The third instance depicts the condition of fluid flowing through the tubes and both the sensors would register the phase difference of the oscillation at the outlet side of the tubes.

The phase difference increases with increasing mass flow.

So far, I have talked about twin-tube measuring technology. In 4-Tube technology, the flow meter is having 4 tubes as shown in the below picture. This means that we have 2 independent measuring systems. There would be four sensors two for each measuring system to register the oscillation of the tubes.

Photo Credits: Endress+Hauser

The controller inside would compare both the sensor-registered oscillations and give more accurate readings.

Technical Benefit of 4-Tube Technology Mass Flowmeter

- The pressure drop would be less as compared to twin-tube technology.

- Higher flow capacity.

- Faster loading and unloading of vessels or oil tankers due to higher flow capacity.

- Higher measuring accuracy compared to twin-tube technology.

Final Thoughts

Endress+Hauser claims that this technology has been demonstrated as one of the most effective techniques for fluids that contain entrained gas or viscous hydrocarbons (heavy oils, bitumen, etc.). The line size is available up to DN 250 (10”).